Coal Ministry Hosts Industry Interaction on Coal Gasification (ET)

- 16 Feb 2024

Why is it in the News?

The Ministry of Coal has announced it will host an Industry Interaction on February 16, 2024, in Hyderabad to discuss the development of coal and lignite gasification projects across India.

What is Coal Gasification?

- Coal gasification is a process where coal undergoes partial oxidation with air, oxygen, steam, or carbon dioxide to produce a fuel gas.

- This gas serves as an alternative to piped natural gas or methane for energy generation.

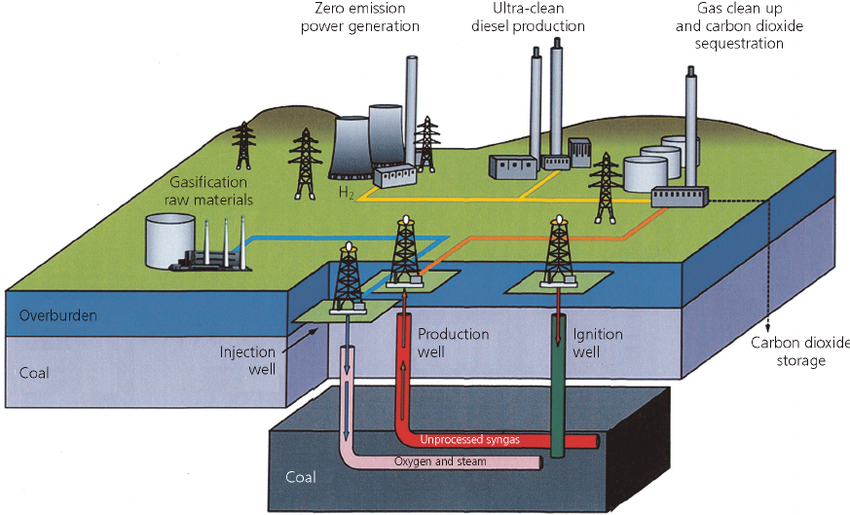

- Underground Coal Gasification (UCG) is a technique involving the conversion of coal into gas within the seam, extracted through wells.

- Production of Syngas: This process yields Syngas, a mixture primarily comprising methane (CH4), carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), and water vapour (H2O).

- Syngas finds applications in producing fertilisers, fuels, solvents, and synthetic materials.

- Significance: In manufacturing, steel companies traditionally rely on costly imported coking coal. Syngas derived from coal gasification offers a cost-effective alternative.

- It is utilized in electricity generation, chemical feedstock production, and hydrogen-based applications like ammonia production and fueling a hydrogen economy.

Advantages of Coal Gasification:

- Coal gasification offers a solution to local pollution issues.

- It is deemed environmentally cleaner than direct coal combustion.

- Decreasing dependence on imported natural gas, methanol, ammonia, and other vital commodities, enhances energy security.

- This technology has the potential to mitigate environmental impacts by curbing carbon emissions and promoting sustainable approaches, aligning with India's global objectives for a more environmentally sustainable future.

Concerns Associated with Coal Gasification Plants?

- The main disadvantage of coal gasification is that it is an expensive process.

- The process can produce a number of harmful emissions, including carbon dioxide, sulphur dioxide, nitrogen oxides, and mercury.

- The process produces a lot of ash, which can pollute the environment.

- The process uses a lot of water, which can lead to water shortages in areas where it is used.