Nano-Coating Technology for Fertilizer Efficiency

- 12 Nov 2024

In News:

A mechanically stable, biodegradable, hydrophobic nanocoating material can enhance the nutrient use efficiency of chemical fertilizers by tuning them for slow release, thereby limiting their interaction with the rhizosphere soil, water and microbes.

Development of Slow-Release Fertilizers:

- A biodegradable, hydrophobic nanocoating has been developed to enhance the nutrient use efficiency of chemical fertilizers.

- The nanocoating allows for slow release of nutrients, thus limiting excessive interaction with soil, water, and microbes, and optimizing fertilizer usage.

Coating Composition:

- The coating is made from nanoclay-reinforced binary carbohydrates, primarily chitosan (a biopolymer from chitin) and lignin (a plant-based polymer).

- These materials are low-cost, naturally derived, and eco-friendly, ensuring sustainability and reducing the environmental impact of fertilizer use.

Technological Innovation:

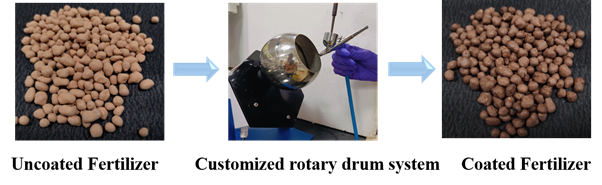

- The coating process involves using a drum rotor method to uniformly coat fertilizers, improving their efficiency.

- The tuning of hydrophobicity in the nanocoating alters the release kinetics of fertilizers, ensuring that nutrients are released in accordance with the crop’s nutrient uptake needs.

Sustainability and Biodegradability:

- The nanocoating is biodegradable, which ensures that it does not harm the environment post-application, unlike conventional chemical fertilizers that may lead to soil degradation and water pollution.

- Life cycle assessment confirms the product's long-term sustainability compared to traditional fertilizers.

Enhanced Crop Productivity:

- The slow-release coating enables a reduced fertilizer dose, while maintaining or even increasing crop yields, particularly for staple crops like rice and wheat.

- This technology facilitates higher agricultural output with fewer inputs, contributing to food security.

Industrial Viability:

- The mechanical stability of the coated fertilizers ensures they can withstand transportation and handling, making them suitable for large-scale industrial application.

- The rotary drum system used for coating ensures uniform application and superior mechanical performance, ensuring that the fertilizers are not damaged during the supply chain process.

Economic Benefits:

- The use of slow-release fertilizers can reduce overall fertilizer costs for farmers while enhancing yields, leading to improved socio-economic conditions for farmers.

- The technology holds potential for economic growth by boosting agricultural productivity and reducing the financial burden on farmers for chemical fertilizer inputs.

Global Relevance:

- The research is significant in the context of global sustainable development goals, aiming to reduce the over-reliance on conventional chemical fertilizers that contribute to soil degradation, water contamination, and greenhouse gas emissions.

Research Collaboration:

- This breakthrough was achieved by scientists from the Institute of Nano Science and Technology (INST), Mohali, in collaboration with the Department of Science and Technology (DST).

- The findings were published in the peer-reviewed journal Environmental Science: Nano, highlighting its scientific validation.