Uttarakhand Tunnel Collapse (Indian Express)

- 21 Nov 2023

Why is it in the News?

On November 12, the under-construction Silkyara-Barkot tunnel on the Yamunotri National Highway in Uttarakhand’s Uttarkashi district collapsed.

News Summary:

- On November 12, 2023, the Silkyara Bend - Barkot tunnel, which was under construction, collapsed in the Uttarkashi district of Uttarakhand.

- The collapse trapped at least 40 workers inside the tunnel.

- The National Disaster Response Force (NDRF), the State Disaster Response Force (SDRF), and the police promptly initiated and led the rescue operations.

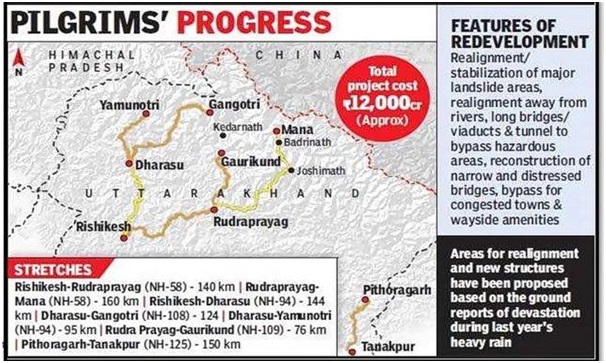

- The tunnel is a part of the Char Dham all-weather road project which commenced in 2016.

What is the Char Dham All Weather Road Project?

- It is a central govt. Project to improve the existing condition of Highways in the state of Uttarakhand.

- In this project, the govt. will upgrade and develop the road which connects all four 'Dhams' i.e.

- Gangotri, Yamunotri, Kedarnath, and Badrinath in the upper Himalayas.

- The 12,000-crore dream project will turn 1100 km of damaged highways of Uttarakhand into all-season roads.

About the Silkyara Tunnel which Collapsed:

- The tunnel, designed to connect Silkyara to Dandal gaon in Uttarkashi district, spans a total length of 4.5 km.

- As part of the Char Dham all-weather road project, this double-lane tunnel is recognized as one of the longest and aims to reduce the journey from Uttarkashi to Yamunotri Dham by 26 kilometers.

- Construction progress includes 2.3 km completed from the Silkyara side and 1.6 km from the Barkot end. Approximately, a 400m stretch of the tunnel is yet to be constructed.

- Regarding the incident:

- The Silkyara Tunnel, located on Uttarkashi-Yamnotri Road, became the site of the accident where workers are currently trapped. The collapse occurred approximately 270m from the entrance on the Silkyara side.

What are the Tunnel Excavation Techniques Utilised in India?

In India, two primary methods of Tunnel Excavation are employed: the drill and blast method (DBM) and tunnel-boring machines (TBMs).

- Tunnel-boring machines (TBMs): TBMs bore into the rock from the front using a rotating head.

- The excavated tunnel section is supported by installing precast concrete segments.

- TBMs are preferred when the rock cover is up to 400 meters in height.

- Notably, the TBM method was applied in constructing tunnels for the Delhi Metro.

- Drill and Blast Method (DBM): DBM involves drilling holes into the rock and loading them with explosives.

- Upon detonation, the rock breaks apart.

- DBM is the chosen method for mountains ranging from 1000 to 1200 meters in height.

- This method is commonly used for tunnel construction in the Himalayas, Jammu & Kashmir, and Uttarakhand.

What could be the Possible Causes of the Tunnel Collapse in Uttarakhand?

- Presence of Fractured or Fragile Rock: Fractured rocks with numerous joints are weaker, making them susceptible to collapse under significant overhead weight, possibly leading to tunnel collapse.

- Water Seepage: Over time, water seepage can erode loose rock particles, creating a void on the top of the tunnel, which might contribute to the tunnel caving in.

- Landslide-Prone Young Himalayan Rock System: The proximity of the incident site to the Main Central Thrust (MCT)/Barkot thrust of the Himalayas raises the possibility that seismic waves could trigger a landslide in the tunnel.

- Improper Study of Shear Zone and Lack of Protection Measures: Experts suggest that the lack of adequate geological mapping studies of the shear zone and failure to implement protective measures, such as steel ribs, rock bolts, or shotcrete, may have contributed to the collapse due to insufficient monitoring.

In addition to these, expert-provided reasons, concerns have been raised about the Himalayas' fragility in supporting massive infrastructure projects like the Char-Dham project and large-scale hydroelectric power projects.

What Measures Have Been Taken to Ensure Safe Tunnel Construction in India?

- Establishment of Tunnel Zone Department in the MoRTH: A dedicated Tunnel Zone department has been set up in the Ministry of Road Transport and Highways (MoRTH).

- Its primary role is to enhance tunneling capabilities and formulate guidelines for the design and construction of tunnels.

- Formation of Expert Committee on Tunnel: An Expert Committee on Tunnel has been constituted to address technical challenges arising during the implementation of tunnel projects across the country.

- Indian Standard Code for Tunnel Construction: The issuance of Indian Standard Codes, specifically IS 15026 (2002) and IS 4756 (1978), provides comprehensive guidelines for tunnel design, lighting, and ventilation.

- Implementation of IRC Codes for Tunnels: The implementation of the IRC code for tunnels in 2019 ensures that road tunnels adhere to international standards.

- Adherence to Standard Codes in Tunnel Construction: Ensuring compliance with various standard codes, including Integrated Tunnel Control Systems (ITCS), The Work in Compressed Air Regulations 1996, Emergency Evacuation and Rescue Plans for tunnels, and guidelines from the Research Designs and Standards Organisation (RDSO).

- Incorporation of International Tunnelling and Underground Space Association Safety Practices: Following safety practices outlined by the International Tunnelling and Underground Space Association, emphasizing specific escape routes marked by signs and the development of contingency plans for emergency situations during tunnel construction.

What Steps Should Be Taken for Ensuring Safe Tunnel Construction?

- Enhanced Geotechnical Studies: In India, the simultaneous design and construction of tunnel projects should be accompanied by more detailed geotechnical studies, including petrographic analysis.

- This information is crucial for incorporating precise design and construction elements into the tunnel project.

- Ongoing Monitoring by Specialist Geologists: Independent specialist geologists should regularly visit construction sites to conduct thorough inspections.

- This practice ensures the early identification of potential failures and helps determine the stand-up time of the rock. (Rock stand-up time refers to the duration for which a rock can remain stable without support.)

- Testing Adequacy of Tunnel Supports: All tunnel supports, such as shotcrete, rock bolts, steel ribs, and tunnel pipe umbrellas, need rigorous testing to ensure their adequacy in preventing tunnel collapse.

- This proactive approach helps in maintaining the stability and integrity of the tunnel structure.

- Emergency Evacuation Arrangements: Robust arrangements for safe evacuation in the event of a collapse are imperative.

- Deployment of National Disaster Response Force (NDRF) personnel, along with the provision of proper safety equipment, is essential. Construction companies bidding for projects should submit comprehensive safety plans as part of their project proposals.